TRANSTIBIAL BIOMECHATRONICS

2020 self-proposed final year thesisProject partner: Carlos aguilera-cortesCompleted.

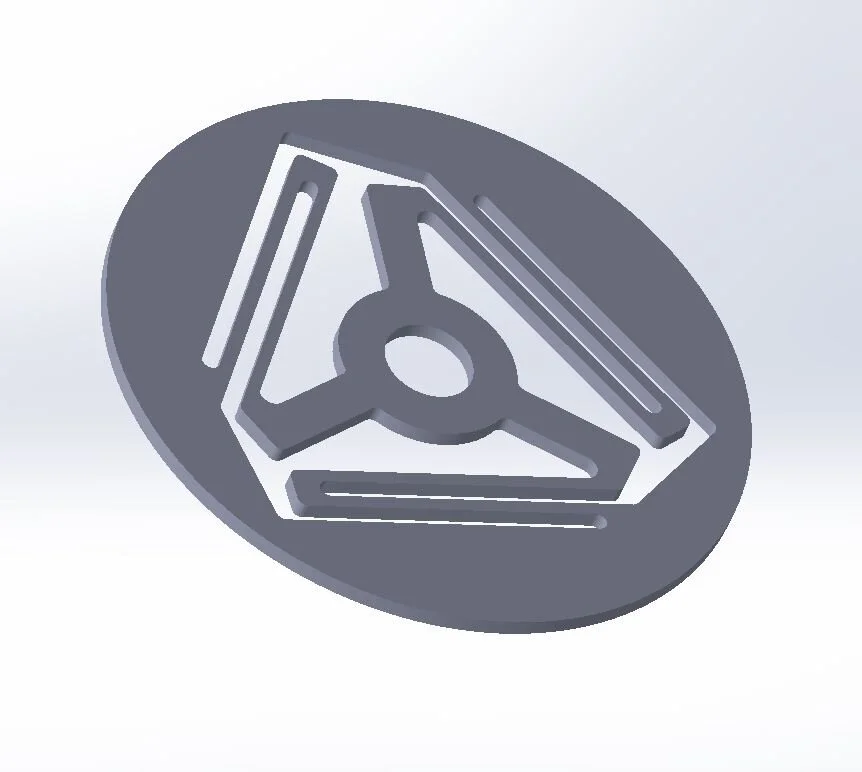

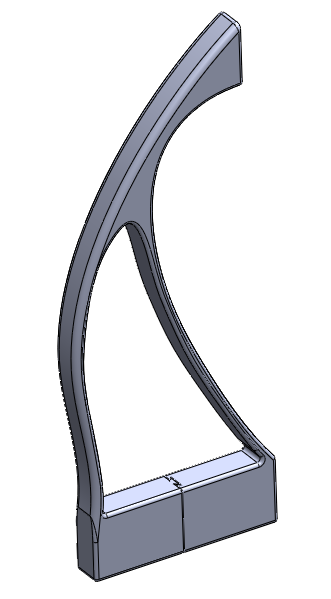

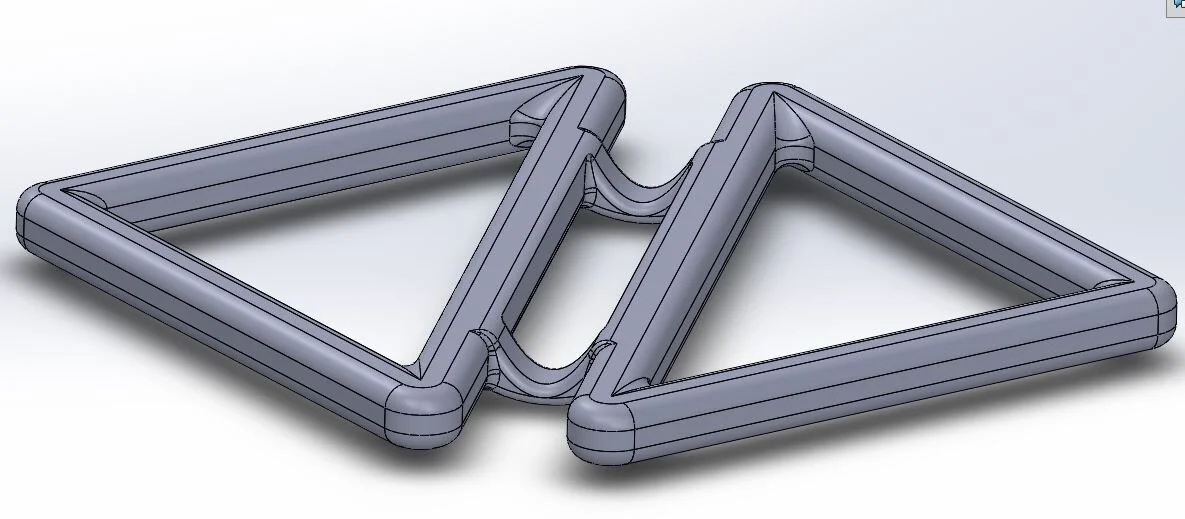

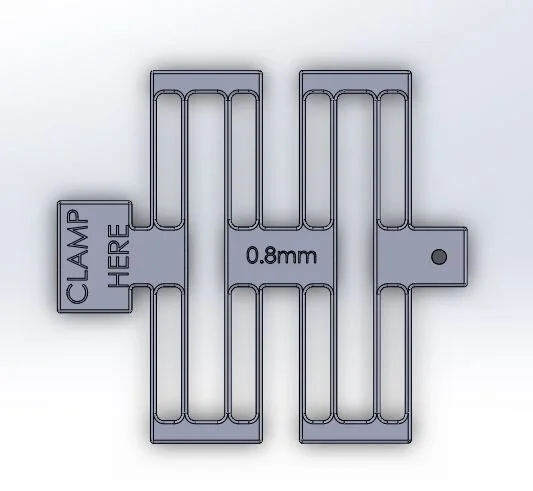

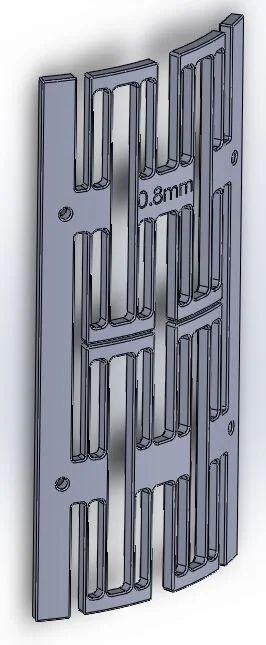

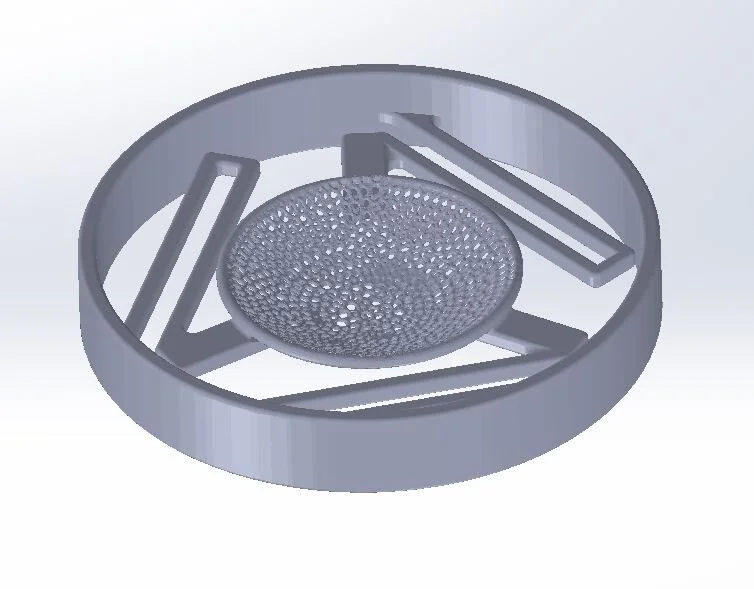

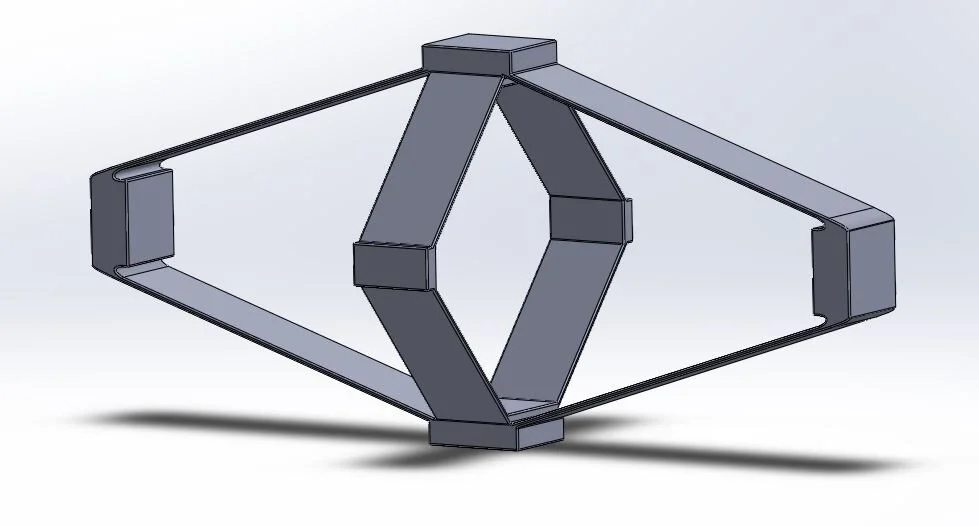

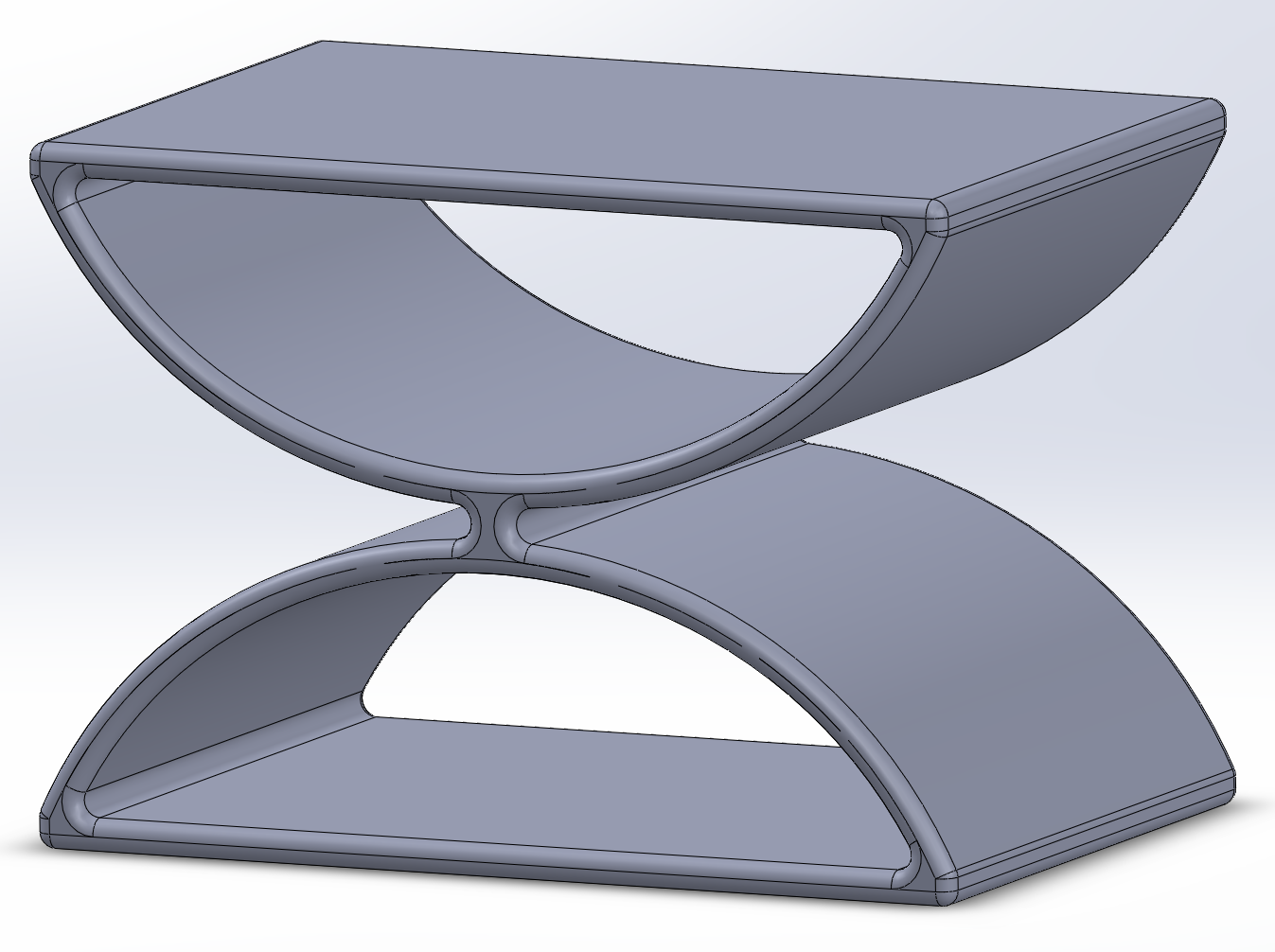

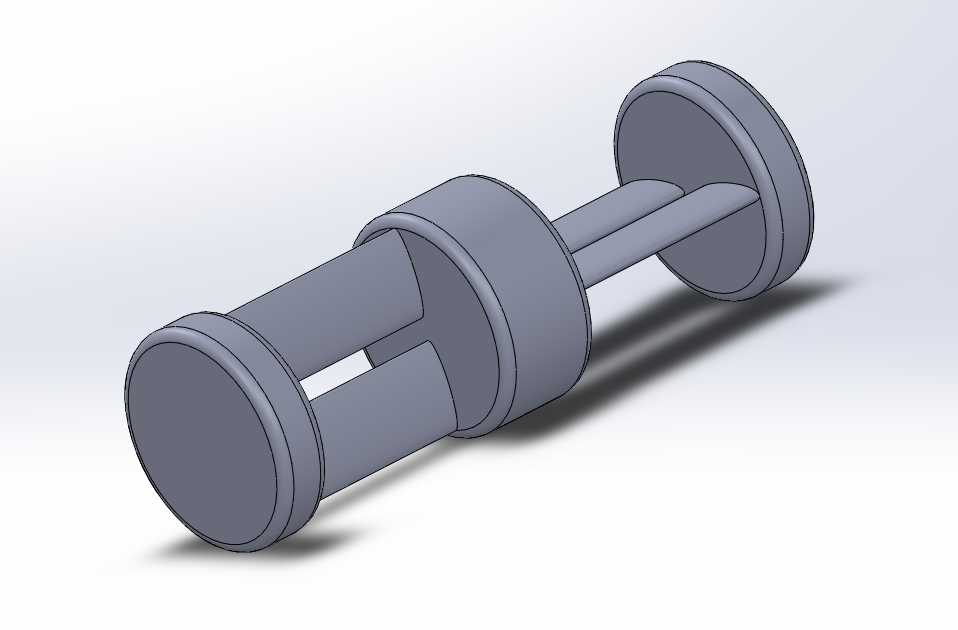

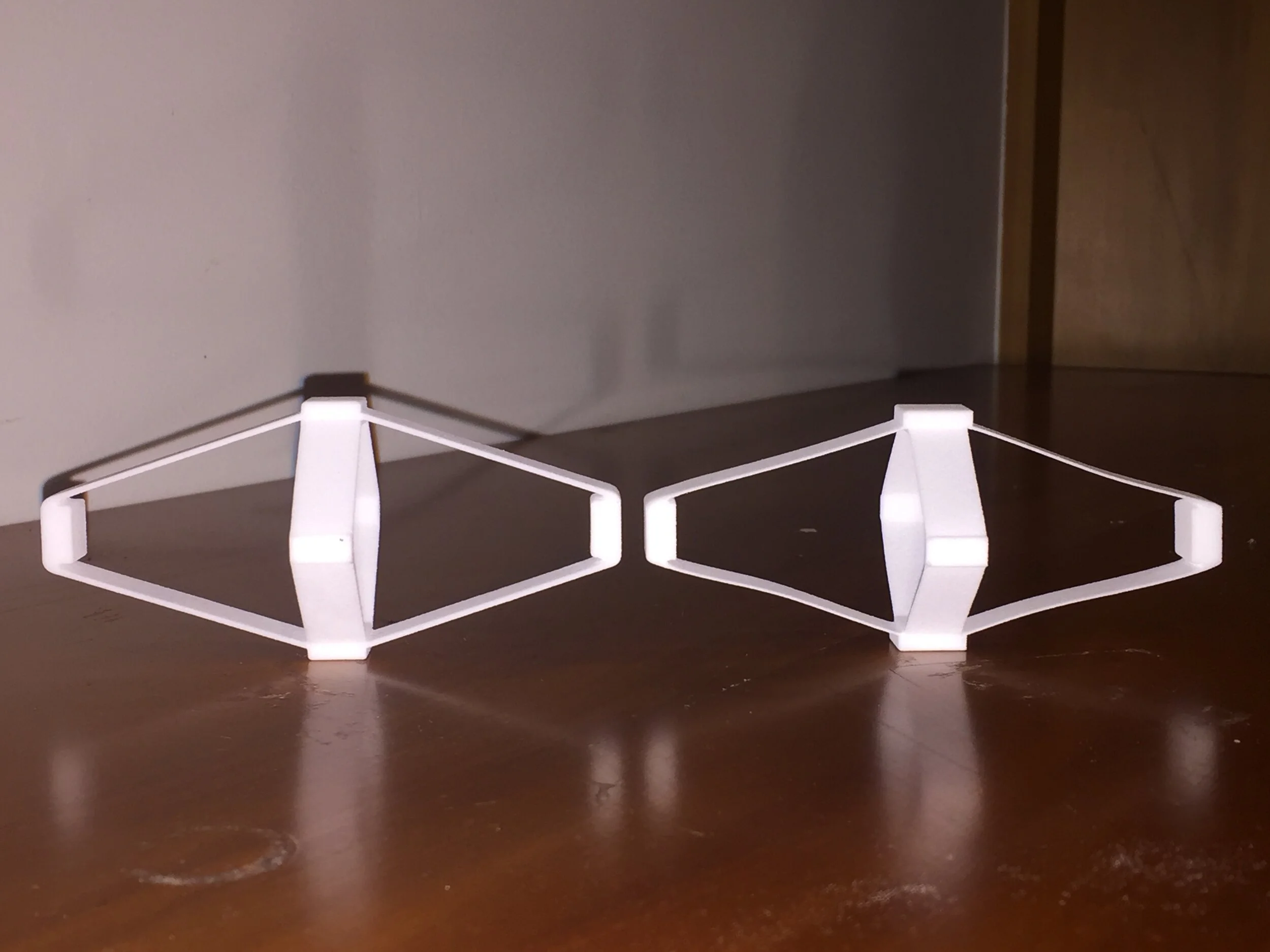

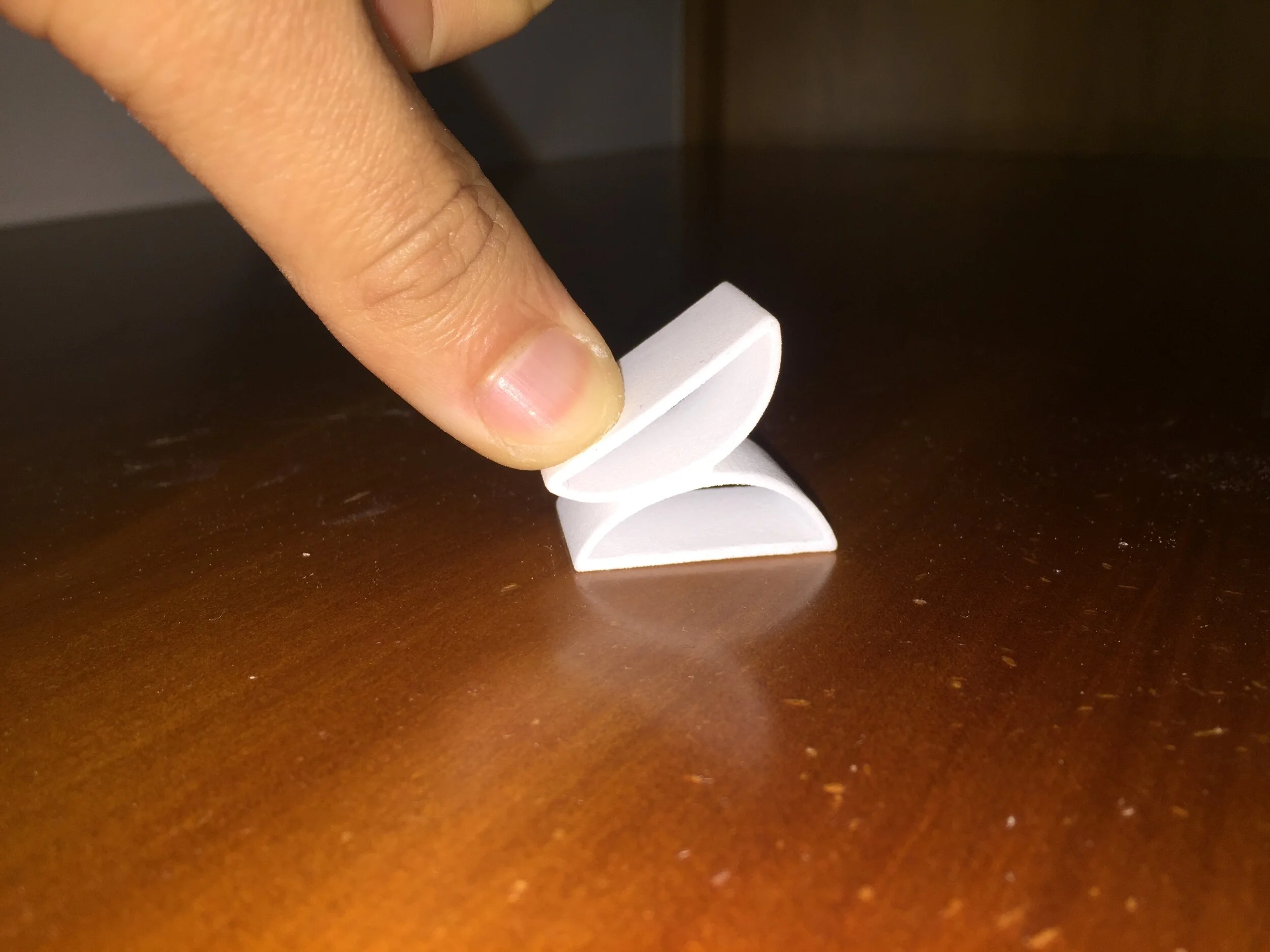

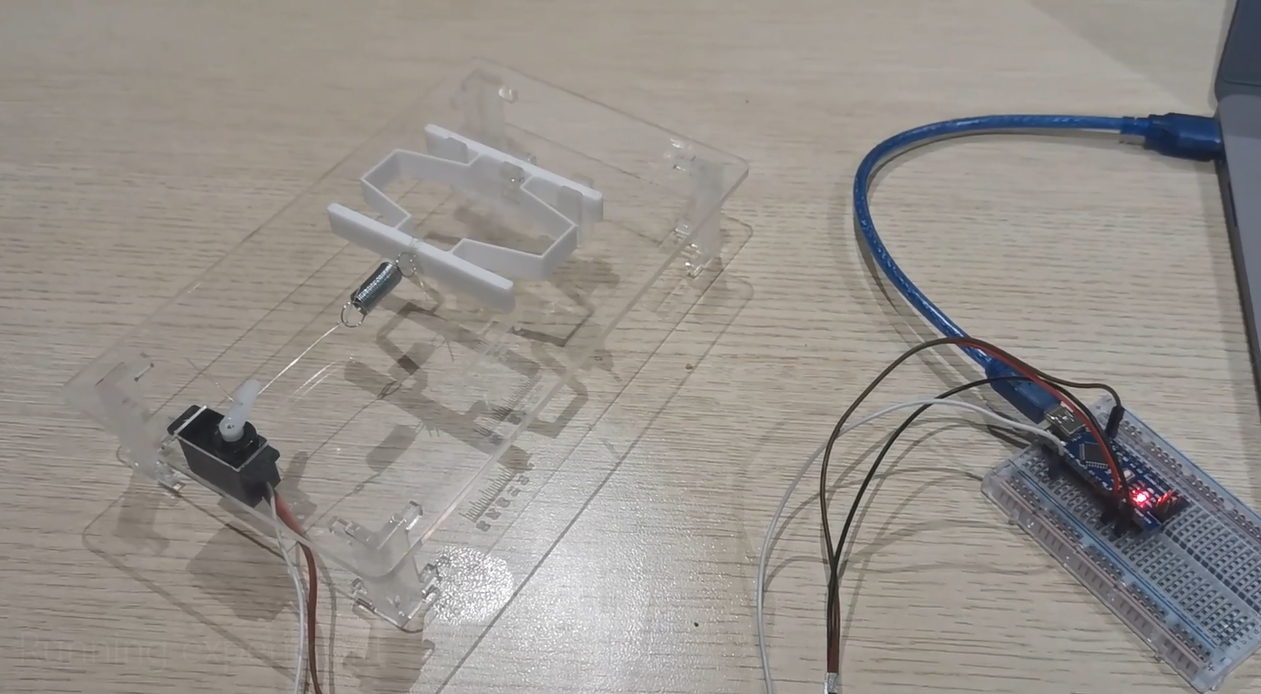

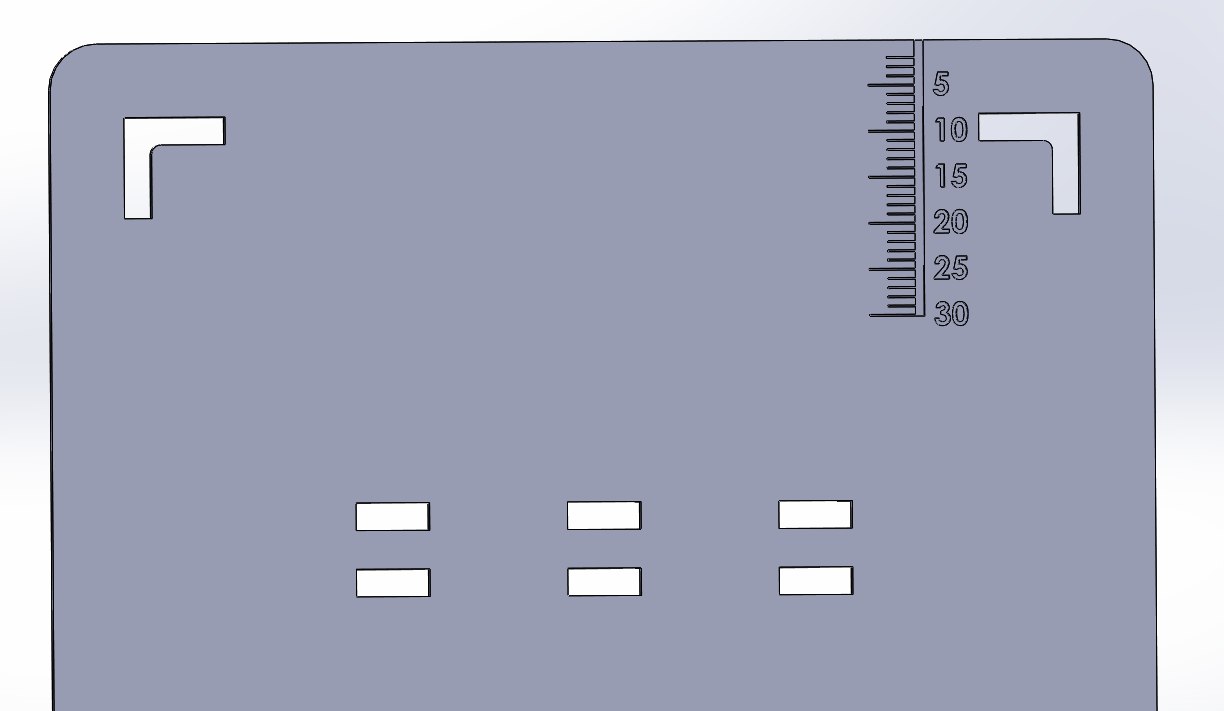

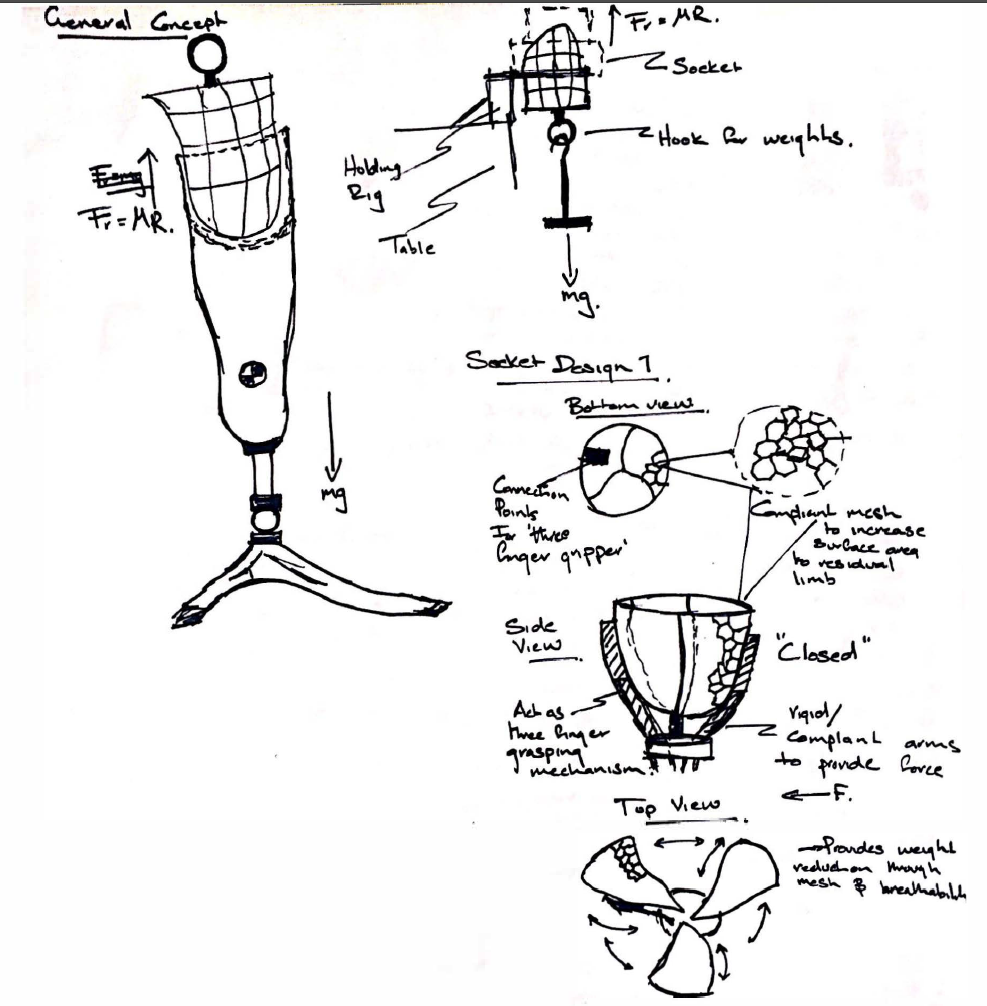

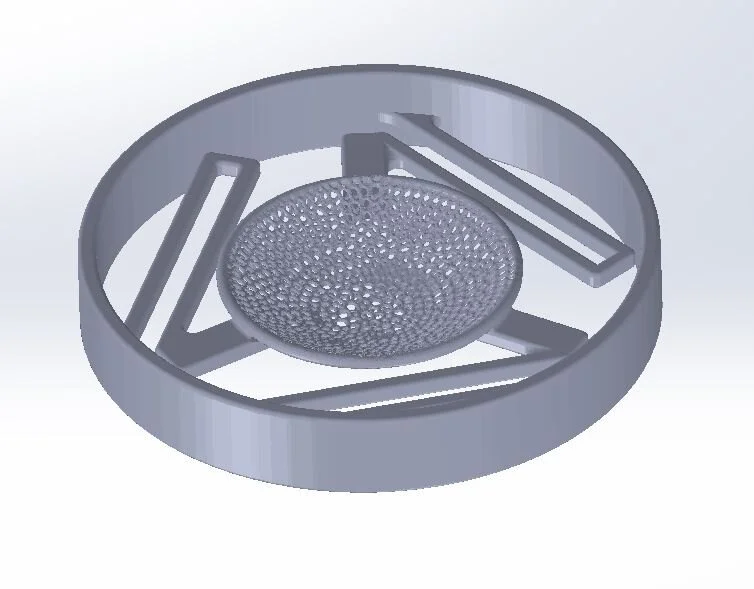

This project was initiated after meeting a transtibial amputee while crossing the road at university. A conversation over coffee led to the discovery of the many pain points transtibial amputees face when selecting a prosthetic socket. This led naturally into a personal project which was pitched to the Creative Design and Additive Manufacturing Lab as a final year engineering project. The project, titled ‘An investigation into selectively laser sintered compliant mechanisms and their applications in biomechatronics and prosthetics’, aims to combine the fields of 3D printing and compliant mechanisms to create high performance, comfortable prosthetic sockets which adapt to the user. Due to the novelty of the field, this project specifically focuses on the creation of compliant mechanisms and their test benches to build a library of mechanisms. From this library, a final product can be created in a modular fashion.