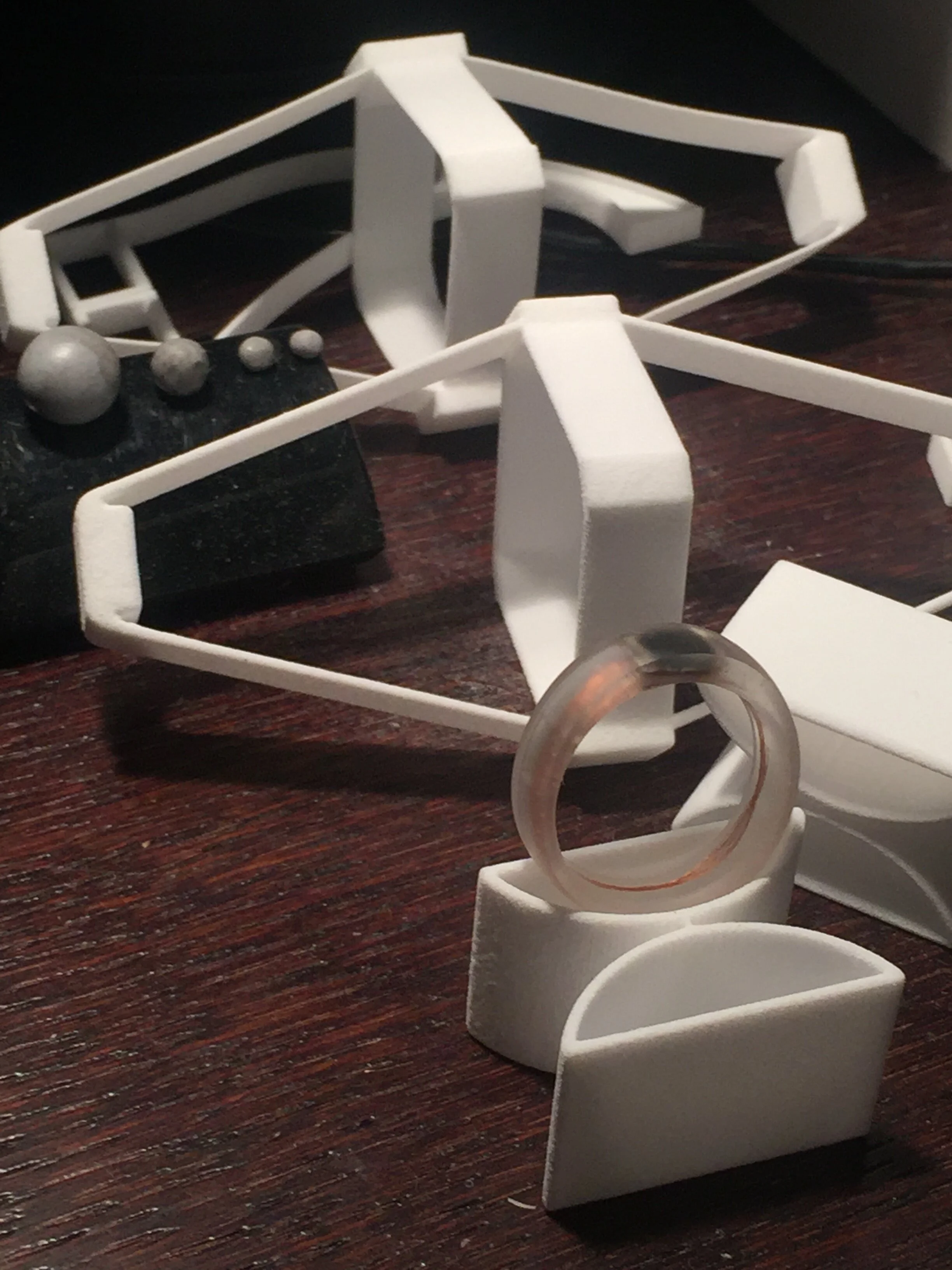

RFID PAYMENTS RING

2019 - 2020 Completed.

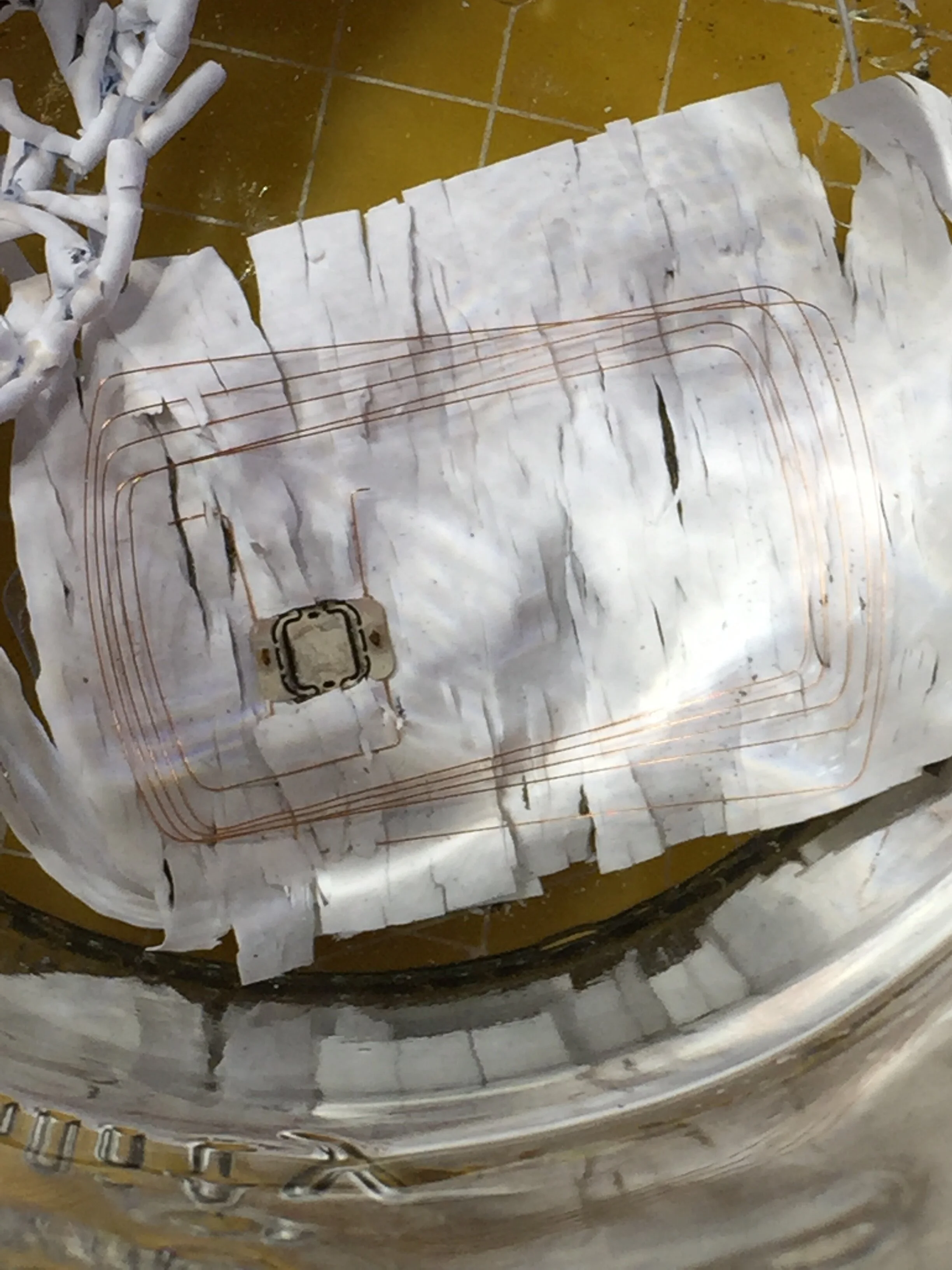

A mini-project that taught about both RFID technology and the inner workings of EMV (Europay, Mastercard and Visa) chips. Turning a pay wave card into a wearable ring simplifies a user's wallet and items they carry around. It also makes payment seamless as all it takes is the wave of a hand. Unfortunately, this ring can no longer be made as the internal card technology has changed from a direct copper antenna to an inductively coupled aluminium antenna. However, if the impedance and capacitance were calculated correctly, one could recreate and solder a direct copper antenna straight to the new EMV chip designed for inductive coupling.

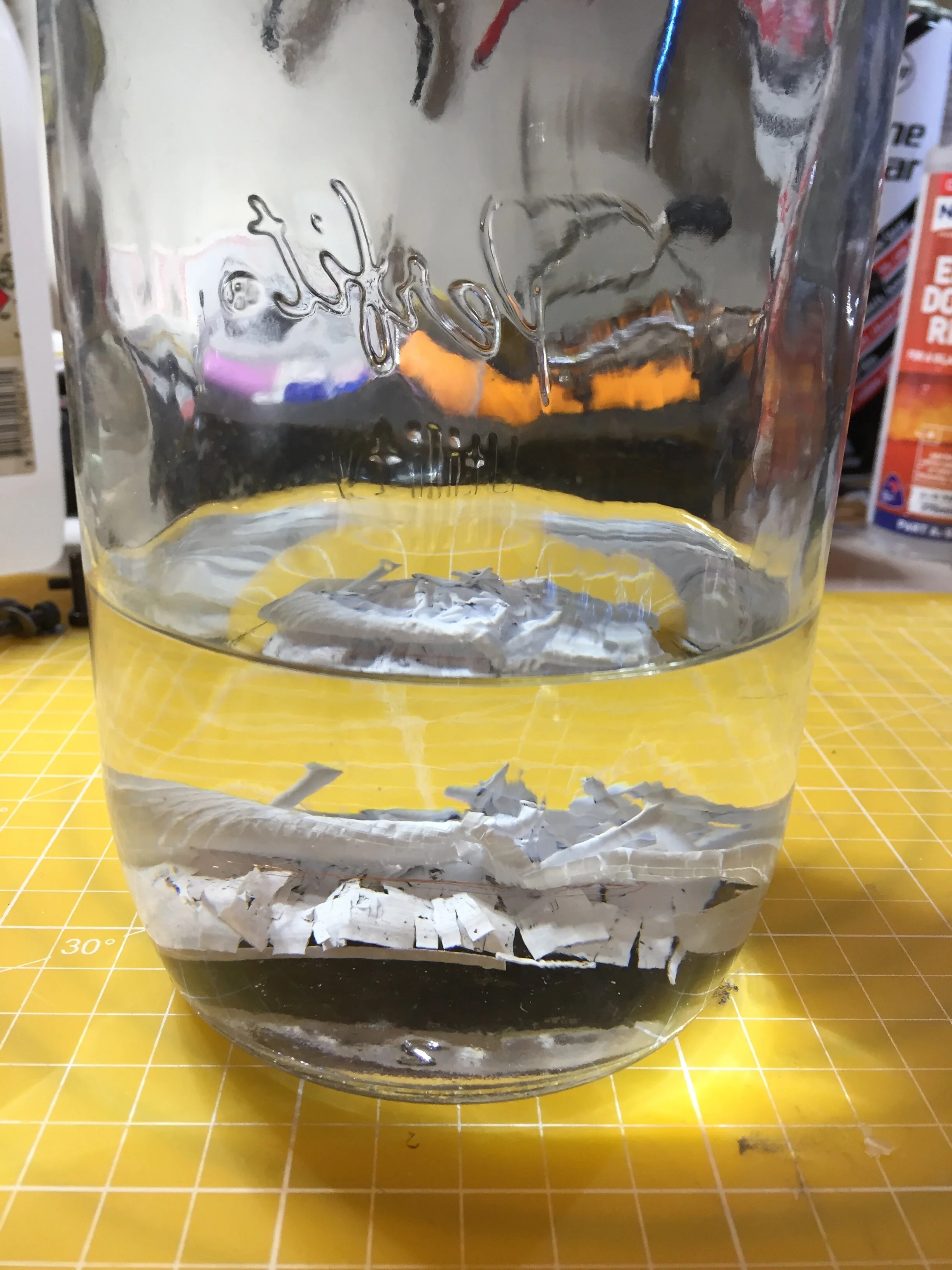

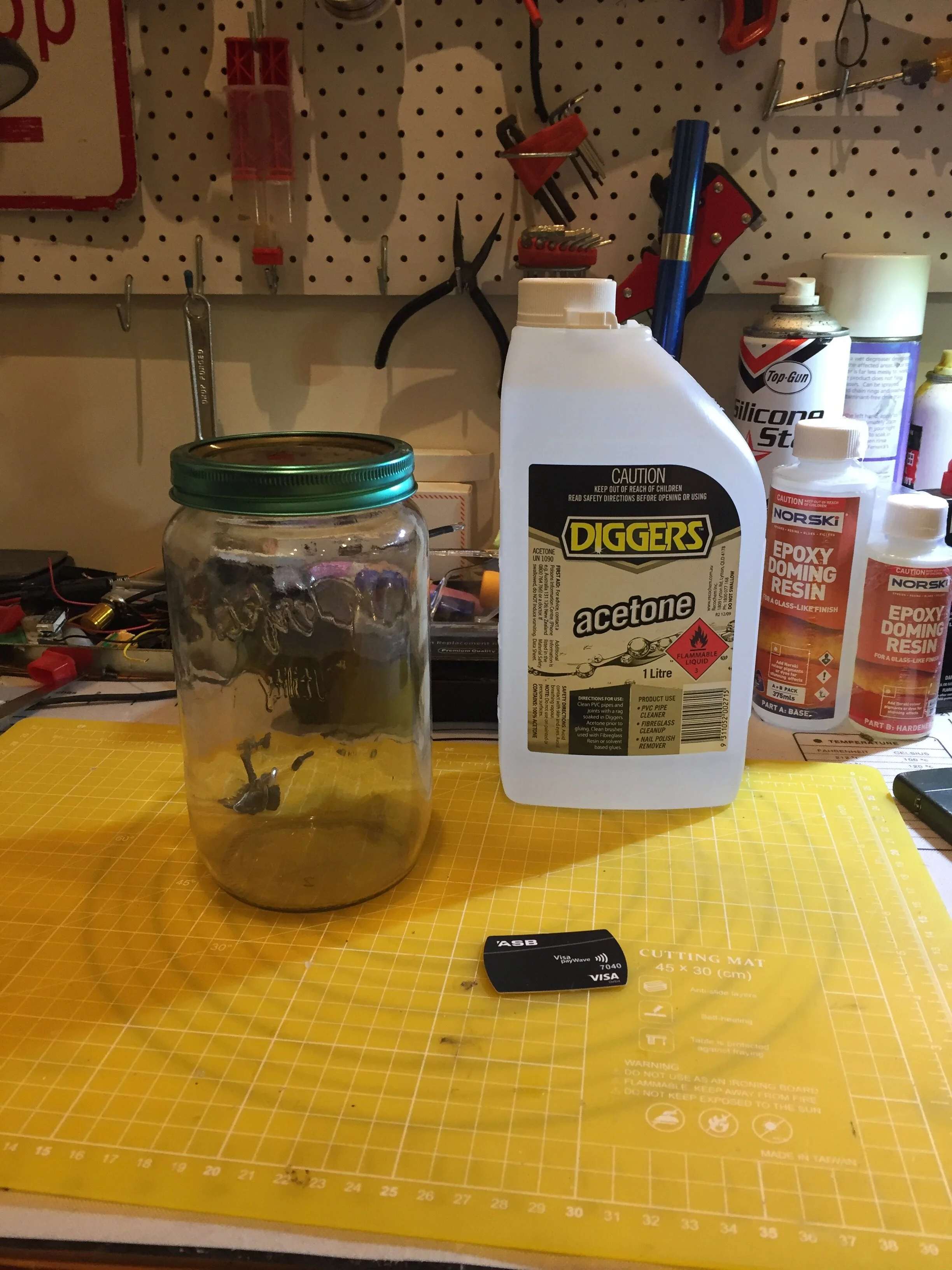

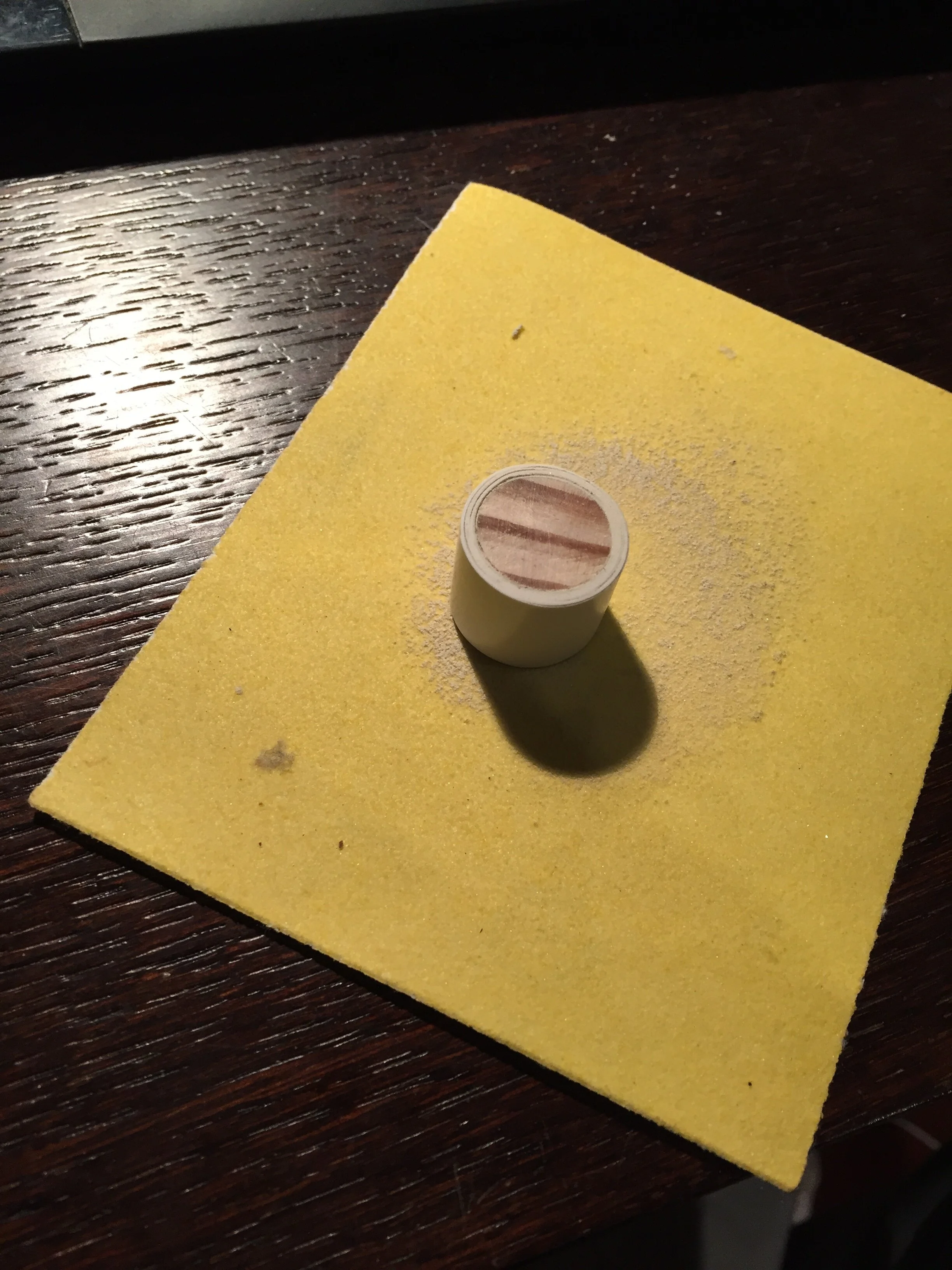

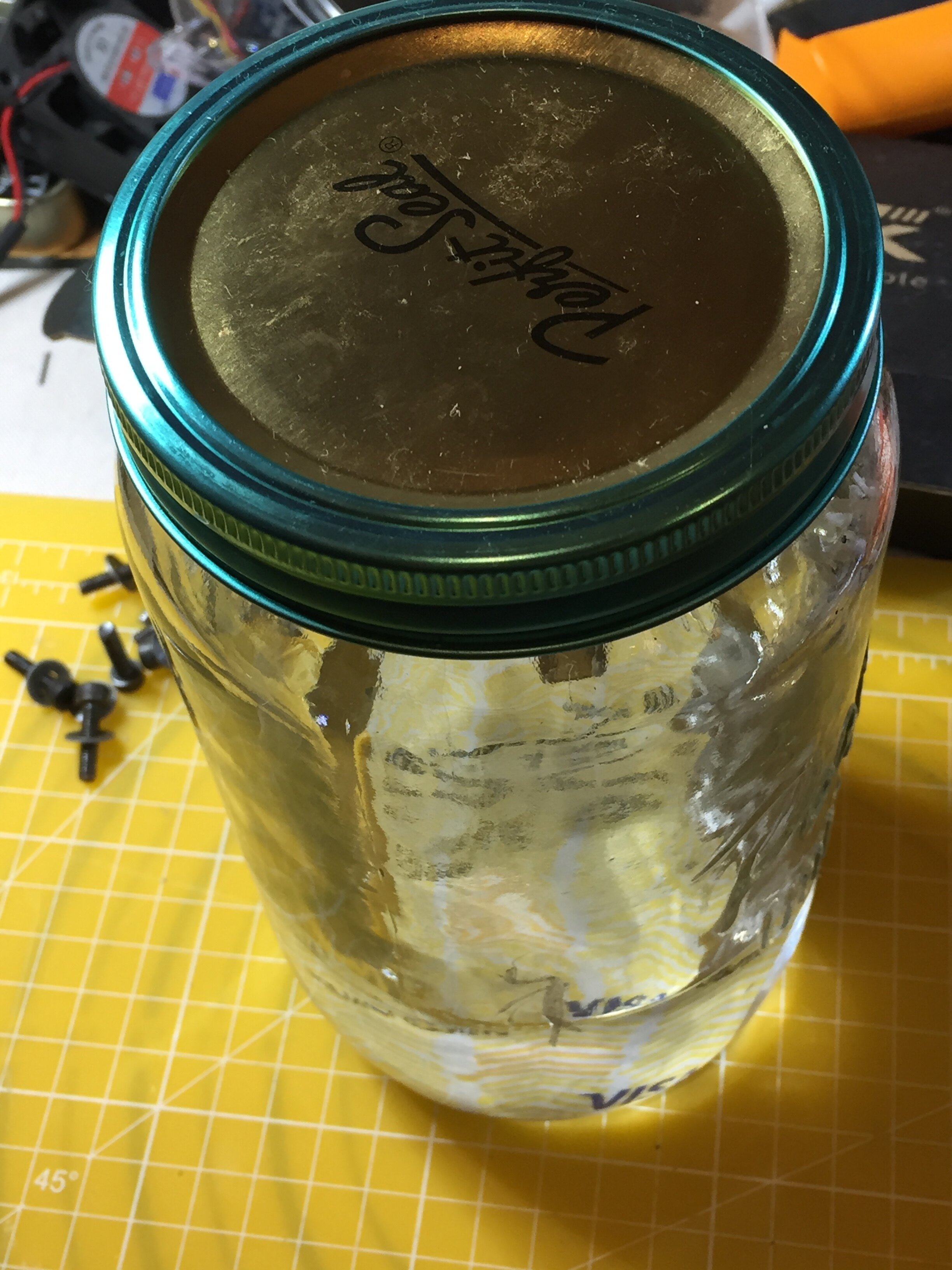

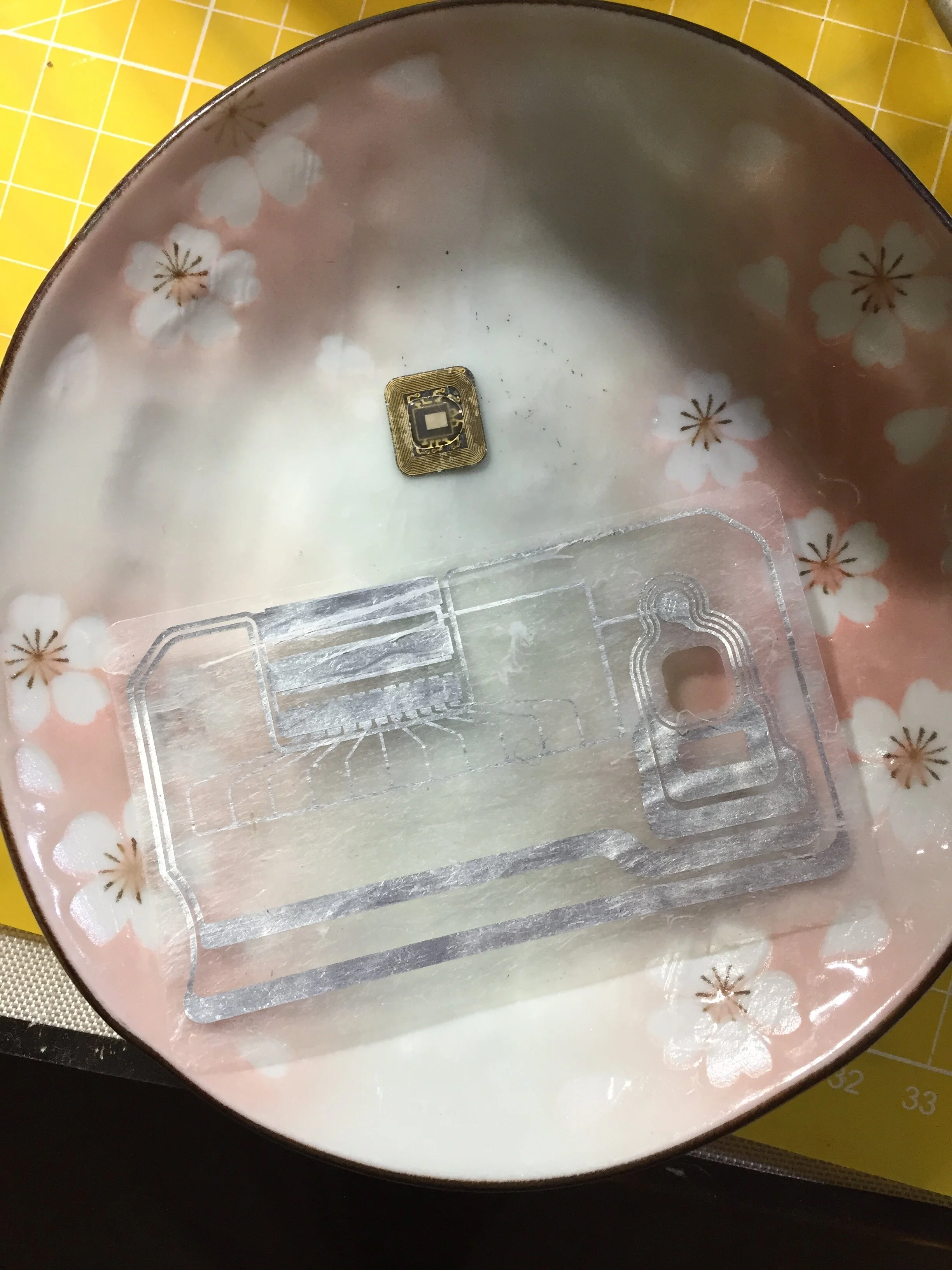

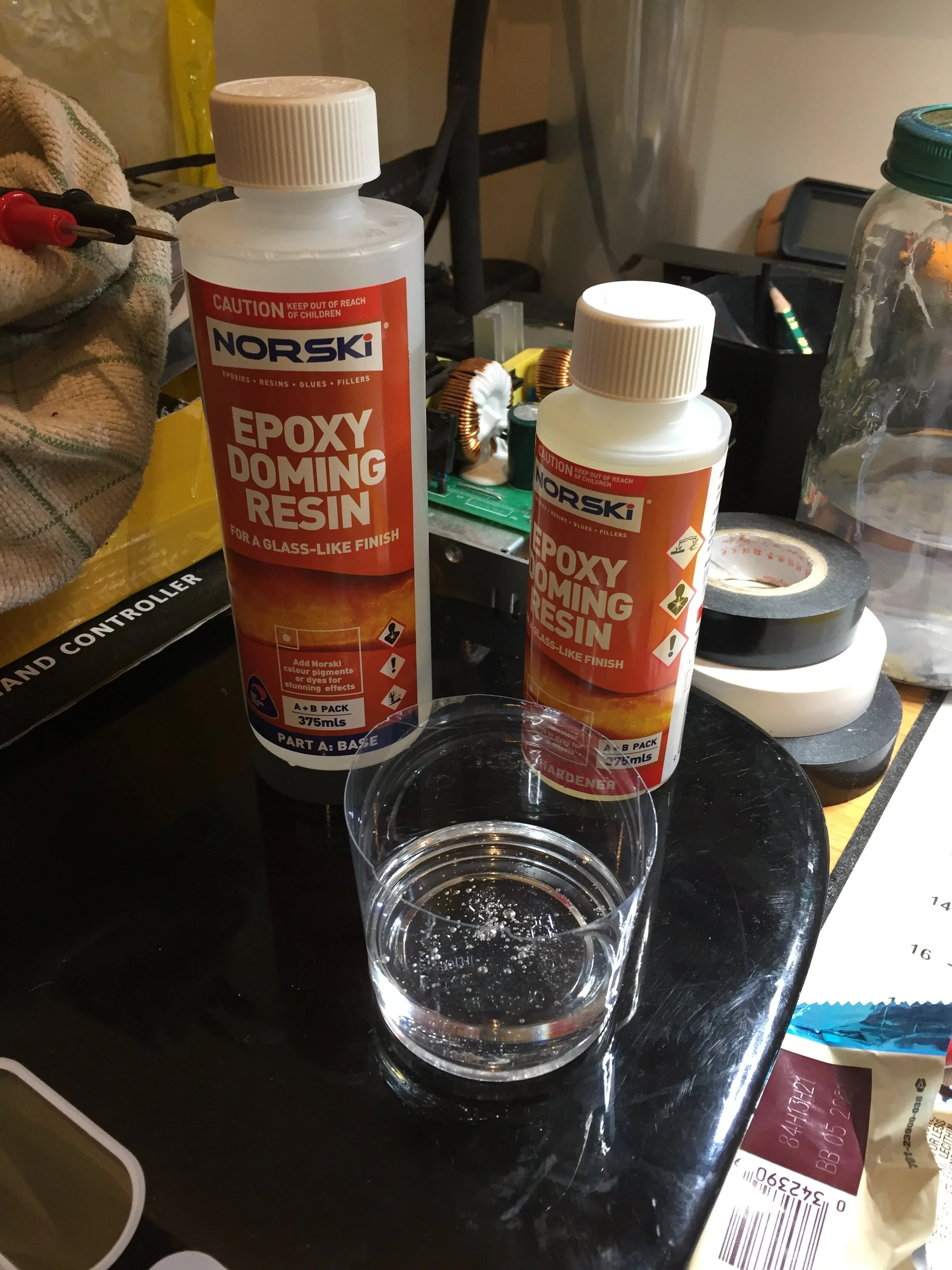

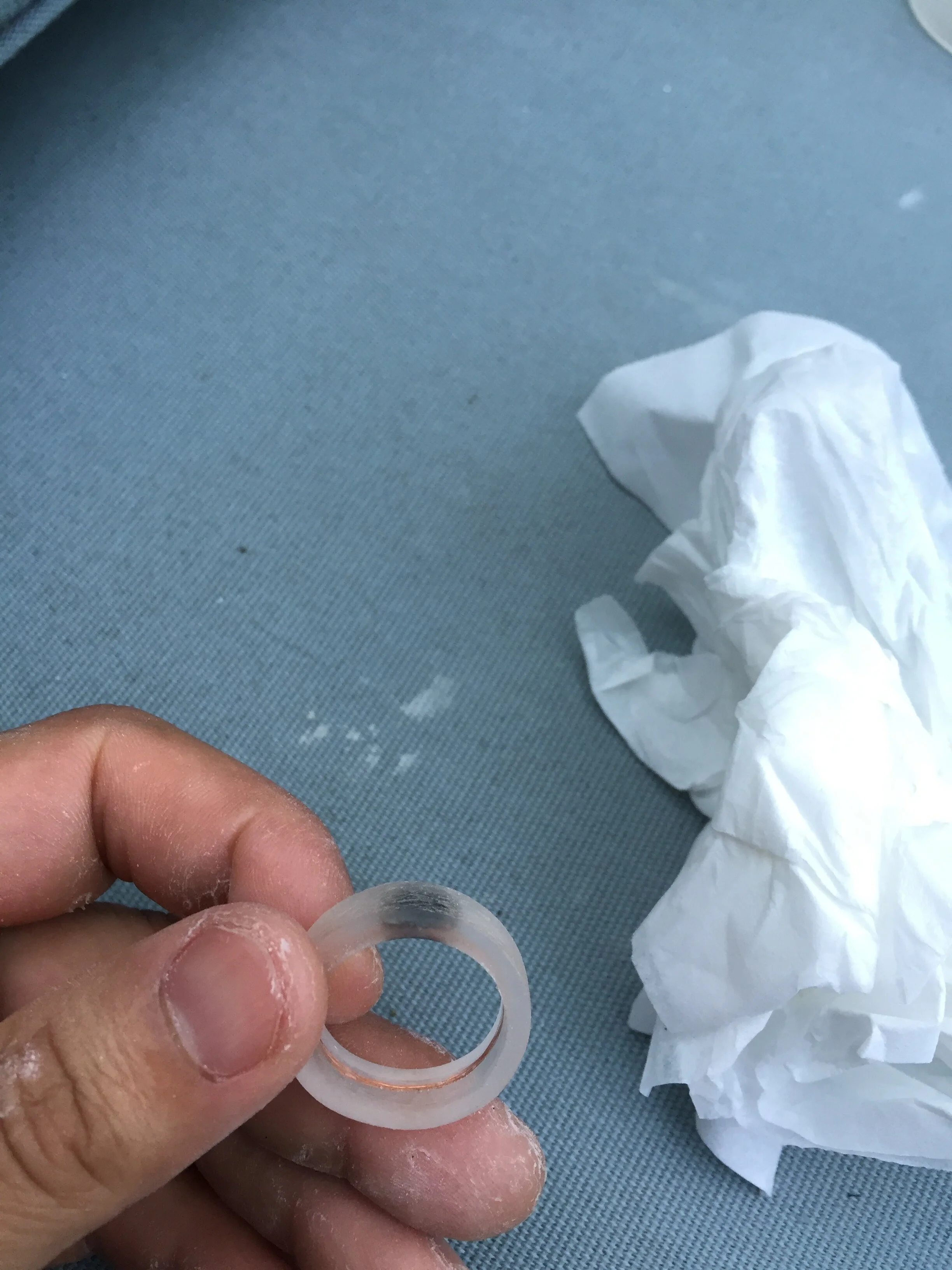

The ring is created by first dissolving the paywave card in acetone which strips the outer plastic/acrylic layers. This reveals the chip and copper antenna that do not dissolve under acetone and are covered through enamel coatings. From here, the antenna is wound around the ring mould taking care not to sever the wire or damage the chip, and the ring is tested to ensure functionality. Doming epoxy resin is then pouring over the ring mould. The hot air from a hairdryer is passed over the mould surface to help the resin flow into the mould and get rid of gas bubbles inside the resin mixture. Once the resin has been set, it is filed, sanded and wet sanded to achieve a clear finish.

The finished ring